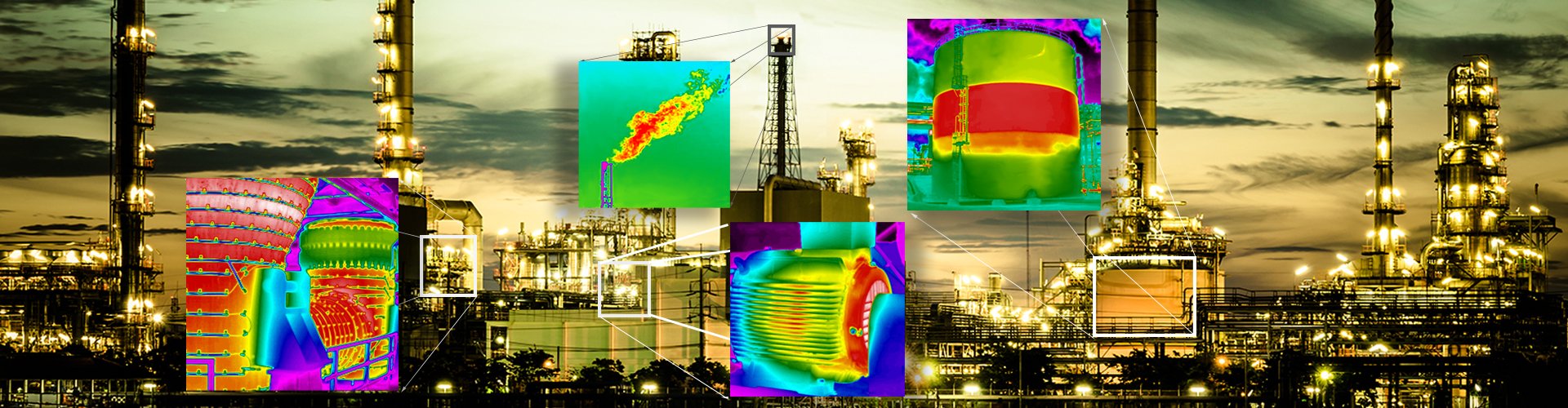

Infrared thermal imaging makes it impossible for the human eye to directly see the surface temperature distribution of the target, and becomes a thermal image representing the temperature distribution of the target surface that can be seen by the human eye. The development of infrared technology has increased the human senses from five to six.

Electric power is the lifeline in a national economic development, so the power equipment becomes the key transportation lifeline in this channel. The working condition quality of the power equipment directly affects the lifeline. The kinds of power equipment are various, complex and in 24 hours of uninterrupted operation. Therefore the types of faults are diverse, but most those have heating phenomenon. Thermal imaging is a new technology. It has a lot of advantages in the detection of electric power equipment running status. Thermal imaging detection of the equipment is on the basis of thermal distribution of the equipment running state. It has lots of advantages in detection, such as uninterrupted, not contact, long distance, fast, and directly.

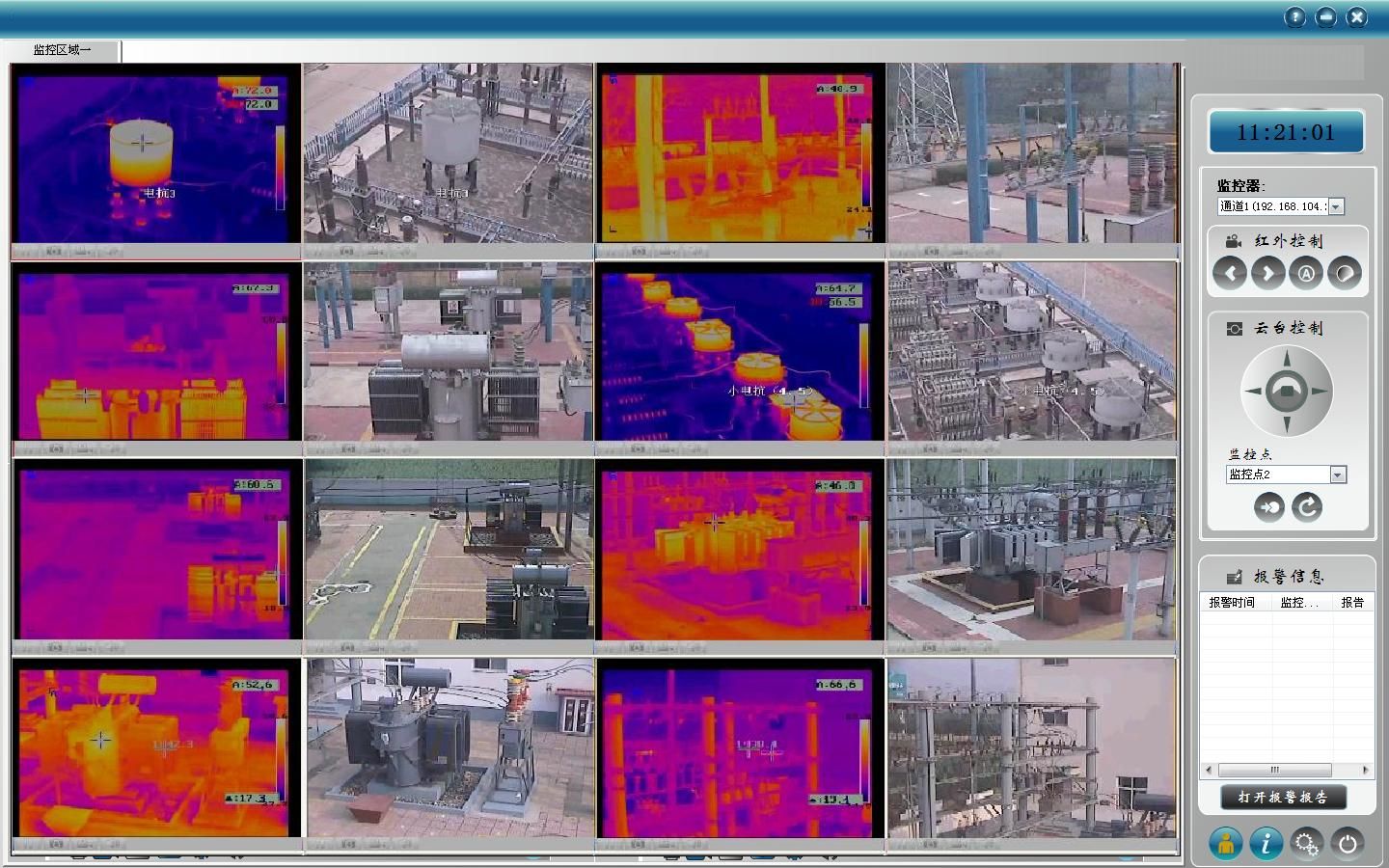

It can work alone. The front-end thermal imaging camera completes all the temperature measurement work, which will transmit infrared images and the original temperature measurement data to the information center or site work station,making the images out of signal compression, loss of signal and strong sense of anti-interference performance. It fundamentally guarantees the accuracy of the temperature data and stability.

This system is round-the-clock operation, and it will not be influenced by natural environment, whether wind and rain, low temperature, it can achieve uninterrupted automatic monitoring, also no worry about the remaining power device.

The bit resolution of thermal imaging camera itself is higher than the precision and resolution of the portable instrument, meanwhile when thermal imaging camera and zoom in visible light camera are installed to the same holder, this device can not only guarantee that the two cameras are monitoring the same setting point, but also it solved the problem of thermal imaging camera's difficulty to identify the equipment installation location. This device facilitates the immediate judge of specific hot spots of instruments, providing precious time for accurate judge and adopting corresponding measures.

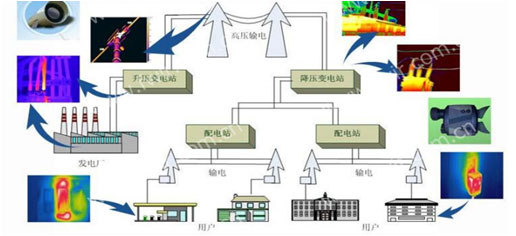

Infrared is usually applied to the following power equipment condition monitoring and fault diagnosis.

1.high voltage electrical equipment running status detection and inside and outside the center of fault diagnosis

2.various conducting joint, clamp, connection and bad connection pile head oxidation corrosion defects

3.various high-voltage switch contacts being exposed flaws within the center

4.Isolating Switch blade with the contact pad and the rotating ball cap with the combination of bad defects

5.overheating capacitor, coupling capacitor and the short of petroleum oil poor insulation (low oil level) defects

6.various types of arrester moisture within the center of defects, the aging of components within the center or non-linear characteristics of mutation and the defect

7.generator State Test, brush and collector ring contact state detection, overheat detection within the center

8.Box abnormal overheating of power transformers, eddy current overheating, high and low pressure casing upper and lower ends of a bad connection

9.various types of motor bearing bad contact, and inside and outside the center of abnormal overheating.